1. Executive Summary:

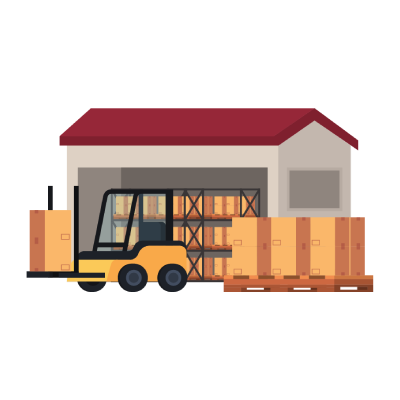

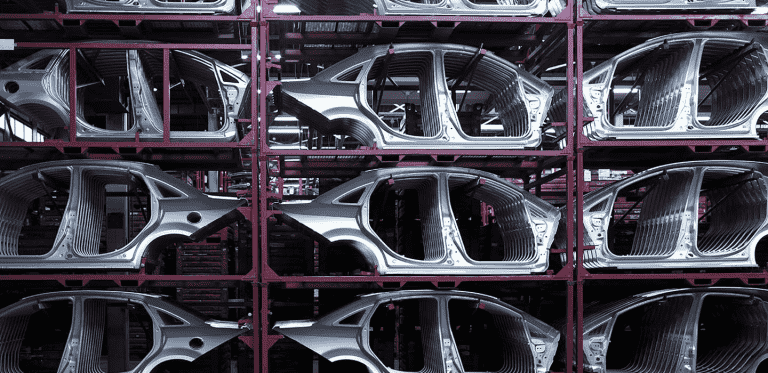

This project focuses on implementing metal pallets within an Automated Storage and Retrieval System (ASRS) for storing paint buckets in a paint manufacturing company.The initiative aims to streamline the storage process, enhance efficiency,and reduce costs.

2. Introduction:

The Paint Company identified the need to optimize its storage system to cope with increasing production demands.The decision to integrate metal pallets within an ASRS was made to improve space utilization and overall logistics efficiency.

3. Implementation Journey:

- Assessment and Planning: The project began with a comprehensive analysis of theexisting storage system, identifying bottlenecks and inefficiencies.

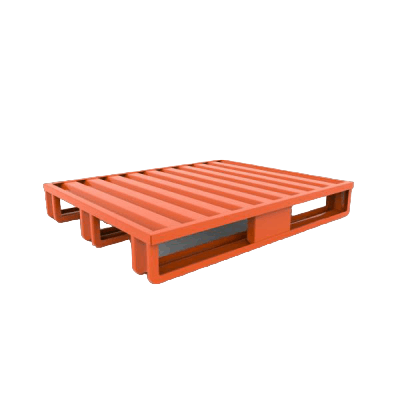

- Selection of Metal Pallets: After thorough research, metal pallets were chosen for their

durability, strength, and suitability for automated systems. - Integration with ASRS: The ASRS, equipped with robotic arms, was configured to work

seamlessly with the chosen metal pallets. - Employee Training: Staff underwent training to adapt to the new system, emphasizing

safety measures and efficient handling of metal pallets.

4. Benefits:

- Optimized Space Utilization: Metal pallets, with their standardized dimensions, maximize vertical storage within the ASRS, efficiently utilizing available space.

- Enhanced Durability: Metal pallets provide a sturdy and durable solution, ensuring longevity and minimizing the need for frequent replacements.

- Automated Retrieval: ASRS automates the retrieval process, reducing manual labor, and increasing overall efficiency.

- Cost Savings: The implementation of metal pallets in the ASRS has led to significant cost savings through improved space utilization and reduced labor requirements.

5. Overall Process Improvement:

- Efficient Storage: Metal pallets enable the systematic storage of paint buckets,reducing the risk of damage and facilitating organized retrieval.

- Reduced Downtime: The ASRS ensures swift and accurate retrieval,reducing downtime associated with manual handling.

- Inventory Accuracy: The automated system enhances inventory accuracy, reducing the chances of errors in stock levels.

6. Conclusion:

The integration of metal pallets in an ASRS has proven to be a successful venture for the Paint Company. It has not only optimized storage space but also enhanced overall efficiency, reducing operational costs and ensuring a streamlined workflow.

7. Recommendations for Future Improvements

- Regular Maintenance:Implement a routine maintenance schedule to ensure the longevity of both the metal pallets and ASRS components.

- Continuous Training: Provide ongoing training to employees to keep them updated on the latest features and safety measures associated with the automated system.

This project showcases the Mattress Company’s commitment to innovation and efficiency by adopting metal stillage for mattress roll storage. It has not only addressed current storage challenges but also positioned the company for future growth and improved operational capabilities.