Automated Storage and Retrieval Systems (ASRS) have transformed the logistics and warehousing industry by significantly enhancing efficiency and accuracy. Central to this revolution is the ASRS pallet, a critical component designed to work seamlessly within these sophisticated systems. Understanding the benefits and applications of ASRS pallets can help businesses make informed decisions to optimize their storage and retrieval processes.

What is an ASRS Pallet?

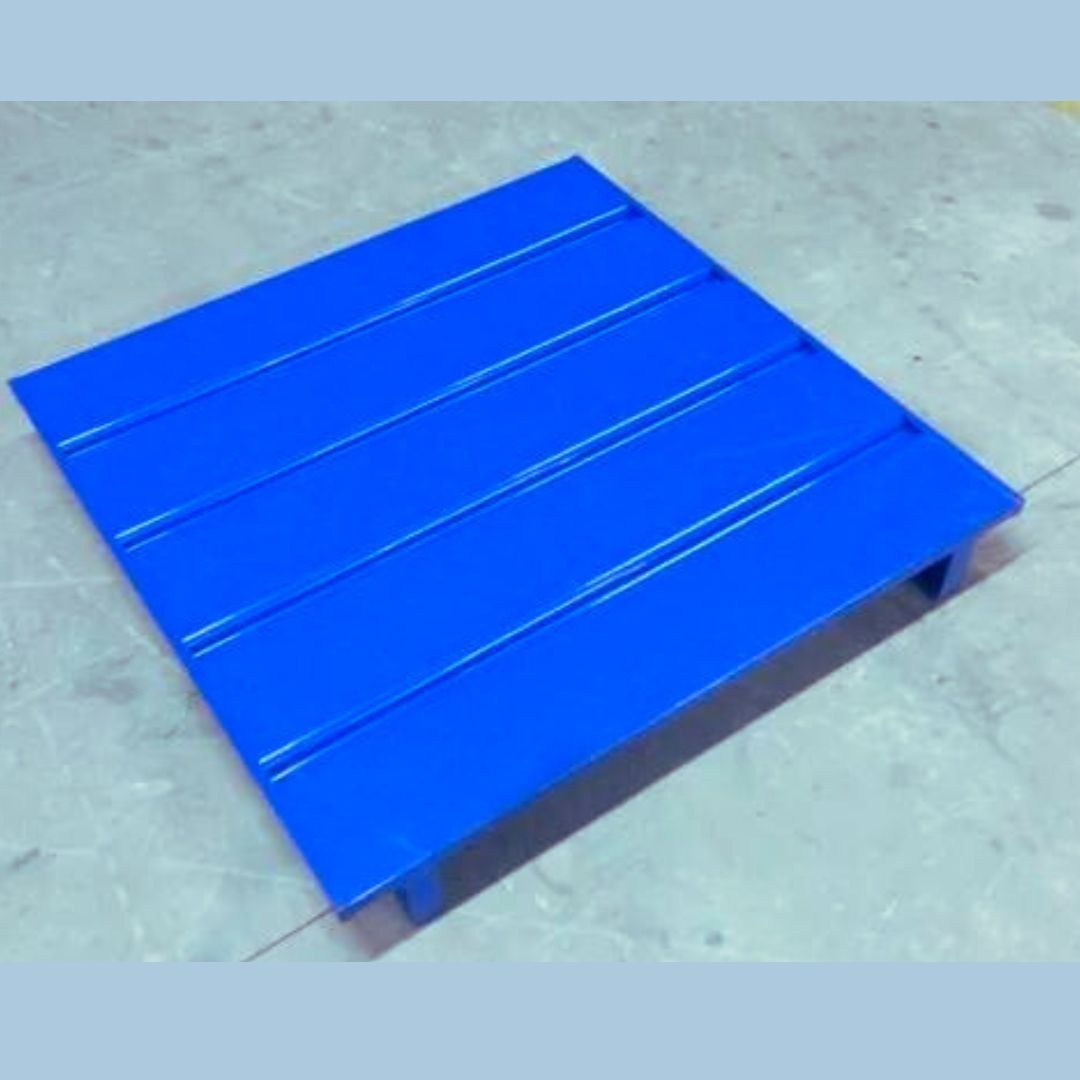

An ASRS pallet is a specially designed pallet used in automated storage and retrieval systems. These pallets are engineered to integrate with ASRS technologies, facilitating the smooth movement, storage, and retrieval of goods. Unlike conventional pallets, ASRS pallets are built to meet the stringent requirements of automation, ensuring compatibility with robotic systems, conveyors, and automated cranes.

Key Features of ASRS Pallets

- Precision Design: ASRS pallets are manufactured with precise dimensions and high tolerances to ensure they fit perfectly within the ASRS infrastructure. This precision minimizes the risk of jams or malfunctions during automated operations.

- Durability: Made from robust materials such as high-grade plastics, metals, or composite materials, ASRS pallets are designed to withstand the rigors of continuous use in automated systems. Their durability ensures a longer lifespan compared to standard pallets.

- Standardization: These pallets adhere to specific industry standards, ensuring interoperability with various ASRS equipment. This standardization allows for seamless integration and compatibility across different automated systems.

- Enhanced Load Capacity: ASRS pallets are designed to handle heavier loads, ensuring they can support the weight of goods typically stored in automated warehouses. This capability is crucial for maintaining efficiency and safety within the system.

Benefits of Using ASRS Pallets

- Increased Efficiency: The integration of ASRS pallets with automated systems significantly reduces the time required for storage and retrieval operations. Automated systems can quickly and accurately locate, pick, and move ASRS pallets, leading to faster order fulfillment and improved productivity.

- Space Optimization: ASRS pallets contribute to better space utilization within warehouses. Their design allows for high-density storage, maximizing the available vertical and horizontal space. This optimization reduces the need for additional storage facilities, leading to cost savings.

- Reduced Labor Costs: By automating storage and retrieval processes, businesses can reduce their reliance on manual labor. This reduction in labor costs, coupled with increased operational efficiency, translates into significant financial savings.

- Enhanced Accuracy: Automated systems, in conjunction with ASRS pallets, ensure high levels of accuracy in storage and retrieval. This accuracy minimizes errors, reduces the risk of damage to goods, and improves overall inventory management.

- Improved Safety: ASRS pallets enhance workplace safety by reducing the need for manual handling of goods. Automated systems can handle hazardous or heavy loads, minimizing the risk of injuries to workers.

Applications of ASRS Pallets

- Manufacturing: In manufacturing environments, ASRS pallets are used to store raw materials, work-in-progress items, and finished products. The automated handling of these pallets streamlines production processes and enhances overall efficiency.

- Retail: Large retailers use ASRS pallets to manage inventory in distribution centers. The automation of storage and retrieval tasks ensures that products are always available for quick dispatch to retail stores or directly to customers.

- Pharmaceuticals: The pharmaceutical industry relies on ASRS pallets to store and manage medications and medical supplies. The high accuracy and reliability of ASRS systems are crucial for maintaining the integrity and safety of pharmaceutical products.

- Food and Beverage: ASRS pallets are used in the food and beverage industry to handle perishable goods. Automated systems ensure that products are stored and retrieved based on their expiration dates, reducing waste and ensuring freshness.

Conclusion

ASRS pallets are a cornerstone of modern automated storage and retrieval systems. Their precision design, durability, and compatibility with automation technologies make them indispensable for businesses aiming to enhance their logistics operations. By leveraging the benefits of ASRS pallets, companies can achieve higher efficiency, improved accuracy, and significant cost savings, ultimately leading to a more streamlined and effective supply chain.

Frequently Asked Questions:-

1. What is an ASRS pallet?

- An ASRS pallet is a specialized pallet designed for use in Automated Storage and Retrieval Systems (ASRS). It is engineered to integrate seamlessly with automated technologies for efficient storage and retrieval of goods.

2. How do ASRS pallets differ from standard pallets?

- ASRS pallets are designed with precise dimensions, high durability, and compatibility with automation equipment, unlike standard pallets. They are built to withstand the rigors of automated systems and meet specific industry standards.

3. What are the main benefits of using ASRS pallets?

- The benefits include increased efficiency, space optimization, reduced labor costs, enhanced accuracy, and improved safety. These advantages contribute to a more streamlined and effective storage and retrieval process.

4. What materials are ASRS pallets made from?

- ASRS pallets are commonly made from high-grade plastics, metals, or composite materials. These materials ensure durability and the ability to handle heavier loads.

5. Can ASRS pallets be used in any automated system?

- ASRS pallets are designed to be compatible with various automated systems. However, it’s important to ensure that the pallets meet the specific requirements and standards of your particular ASRS equipment.