When it comes to efficient material handling solutions, pipe joint trolleys have emerged as a revolutionary innovation in various industries. These trolleys, designed to simplify the movement and management of materials, are indispensable in manufacturing units, warehouses, and assembly lines. As a leading PIPE JOINT TROLLEY MANUFACTURER IN INDIA companies are continuously setting benchmarks in delivering high-quality, durable, and customizable solutions to meet diverse industrial requirements.

Understanding Pipe Joint Trolleys

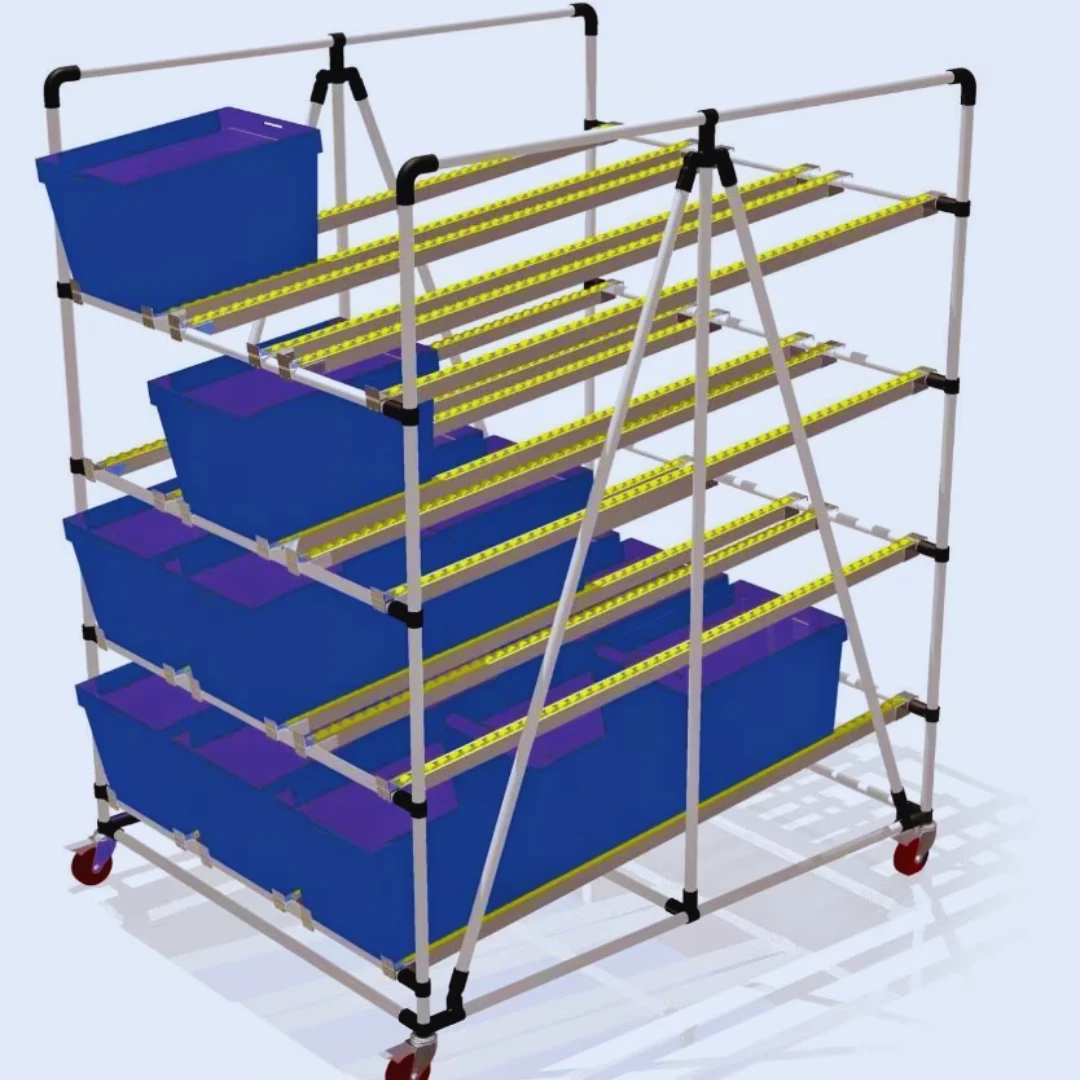

Pipe joint trolleys are modular material handling systems made with pipe-and-joint mechanisms. Their lightweight structure, combined with their high strength and adaptability, makes them ideal for dynamic workplaces. These trolleys are constructed using aluminum or steel pipes, connectors, and wheels, offering flexibility in design and configuration.

The modularity of pipe joint trolleys allows businesses to tailor them according to their specific needs. From transporting small components to heavy loads, these trolleys provide an efficient and ergonomic solution that enhances productivity and reduces manual labor.

Benefits of Pipe Joint Trolleys

1. Customizable Designs

The modular nature of pipe joint trolleys enables customization based on unique requirements. Whether it’s a multi-tiered trolley or a specialized design for a specific workflow, manufacturers in India provide solutions that perfectly align with operational needs.

2. Durability and Longevity

As one of the most trusted PIPE JOINT TROLLEY MANUFACTURERS IN INDIA, the focus is always on durability. These trolleys are constructed with high-quality materials that withstand heavy loads and resist wear and tear, ensuring long-term usage without frequent replacements.

3. Lightweight and Portable

Despite their robust construction, pipe joint trolleys are lightweight, making them easy to maneuver across various industrial spaces. This feature is especially beneficial in fast-paced environments like assembly lines.

4. Cost-Effective

The cost-effectiveness of pipe joint trolleys lies in their modularity and reusability. Components can be repurposed or replaced individually, reducing the need for purchasing entirely new trolleys.

5. Enhanced Workplace Efficiency

By streamlining material movement, pipe joint trolleys improve operational efficiency and contribute to a more organized and productive workplace.

Applications of Pipe Joint Trolleys in Industries

1. Manufacturing Units

Pipe joint trolleys are indispensable in manufacturing units where materials and components need to be transported across various stages of production. Their adaptability ensures smooth operations in dynamic environments.

2. Warehousing and Logistics

In warehouses, pipe joint trolleys simplify the storage and retrieval of goods. Their multi-tiered configurations allow for organized storage, while their mobility ensures seamless logistics operations.

3. Automotive Industry

In the automotive sector, pipe joint trolleys are used to transport heavy parts like engines, tires, and other components, ensuring safety and efficiency.

4. Electronics Assembly

Electronics assembly lines benefit from pipe joint trolleys for transporting delicate components. Their customizable shelves and compartments ensure safe handling of fragile items.

5. Healthcare Sector

Hospitals and clinics utilize pipe joint trolleys for moving medical supplies, equipment, and even patient records. Their lightweight design and mobility are key advantages in this sector.

Why Choose an Indian Manufacturer for Pipe Joint Trolleys?

India is home to some of the most innovative and reliable PIPE JOINT TROLLEY MANUFACTURERS IN INDIA. With a strong focus on quality, cost-efficiency, and customer satisfaction, Indian manufacturers offer several advantages:

1. Cutting-Edge Technology

Indian manufacturers leverage advanced technology to produce pipe joint trolleys that meet international standards. From automated production lines to stringent quality checks, the emphasis is on delivering excellence.

2. Eco-Friendly Solutions

Sustainability is a priority for Indian manufacturers. Many companies utilize eco-friendly materials and processes to ensure minimal environmental impact while maintaining product quality.

3. Competitive Pricing

The cost advantages of manufacturing in India translate into affordable pricing for clients without compromising on quality.

4. Global Reach

Indian manufacturers serve both home and global markets. Their ability to deliver bulk orders with quick turnaround times makes them a preferred choice worldwide.

5. Customer-Centric Approach

From providing custom solutions to offering after-sales support, Indian manufacturers prioritize customer satisfaction at every step.

How to Select the Right Pipe Joint Trolley Manufacturer?

Choosing the right manufacturer is crucial to ensuring you get the best product for your needs. Here are some factors to consider:

1. Experience and Expertise

Look for manufacturers with a proven track record in producing high-quality pipe joint trolleys. Their expertise ensures reliable and innovative solutions.

2. Customization Capabilities

Ensure that the manufacturer can give personalized solutions to match your individual needs. This includes flexibility in design, size, and functionality.

3. Quality Standards

Check that the producer follows tight quality control standards. Check for certifications and industry accreditations.

4. Pricing and Value for Money

Compare prices among different manufacturers, but don’t compromise on quality. Choose a manufacturer that offers the best value for your investment.

5. Client Reviews and Testimonials

Read reviews and testimonials from previous clients to gauge the manufacturer’s reputation and reliability.

The Future of Pipe Joint Trolleys in India

As industries evolve and adopt more advanced technologies, the demand for efficient material handling solutions like pipe joint trolleys is set to grow. Manufacturers in India are continuously innovating to meet these changing needs. From incorporating smart features like RFID tracking to using lightweight composite materials, the future of pipe joint trolleys looks promising.

Moreover, the rise of Industry 4.0 has opened new avenues for automation and digitalization in material handling. Pipe joint trolleys are being integrated with automated systems, enhancing their functionality and efficiency in modern workplaces.

Conclusion

Pipe joint trolleys are a game-changer in material handling, offering unmatched flexibility, durability, and cost-effectiveness. As a trusted PIPE JOINT TROLLEY MANUFACTURER IN INDIA, companies are committed to delivering top-notch solutions that drive efficiency and productivity across various industries. With a strong emphasis on quality, innovation, and customer satisfaction, Indian manufacturers are paving the way for a more efficient and sustainable future.

For businesses seeking reliable and durable solutions, partnering with a leading MATERIAL TROLLEY MANUFACTURER ensures the perfect blend of quality and value. With customizable options and robust construction, these trolleys are designed to meet the evolving needs of modern industries.

Frequently Asked Questions:-

1. What is a pipe joint trolley, and how is it used?

- A pipe joint trolley is a modular material handling system constructed using pipe-and-joint mechanisms. It is used to transport materials in industries such as manufacturing, warehousing, and automotive assembly, enhancing efficiency and reducing manual labor.

2. Why should I choose an Indian manufacturer for pipe joint trolleys?

- Indian manufacturers offer high-quality, customizable solutions at competitive prices. They use advanced technologies and eco-friendly processes, ensuring reliable and cost-effective products that meet international standards.

3. Can pipe joint trolleys be customized?

- Yes, pipe joint trolleys are highly modular and can be tailored to meet specific operational needs, such as multi-tiered designs, specialized compartments, and varying load capacities.

4. What materials are used in making pipe joint trolleys?

- Pipe joint trolleys are typically made from aluminum or steel pipes, ensuring a balance of lightweight design and robust strength. High-quality connectors and durable wheels are also integral to their construction.

5. How do pipe joint trolleys improve workplace efficiency?

- Pipe joint trolleys streamline material movement, reduce manual effort, and ensure organized workflows. Their portability and adaptability make them essential for improving productivity in dynamic work environments.