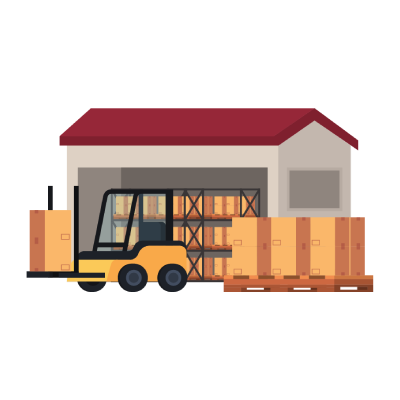

In the fast-paced world of logistics, effective inventory management is crucial for maintaining operational efficiency and customer satisfaction. A well-organized warehouse can significantly impact the speed and accuracy of order fulfillment. One of the keys to achieving this is through the careful selection and use of logistic warehouse storage products. This guide will explore various storage solutions, their benefits, and how they can enhance your inventory management practices.

Table of Contents

ToggleUnderstanding Logistic Warehouse Storage Products

Logistic warehouse storage product are a variety of tools and systems designed to optimize space utilization, improve inventory accessibility, and streamline order-picking processes. These products range from shelves and pallets to advanced automated systems that facilitate better inventory control.

Types of Logistic Warehouse Storage Products

Shelving Units

- Static Shelving: Static shelving systems are the most common form of warehouse storage. They are ideal for smaller items and can be adjusted to fit various inventory sizes. These units can be made from different materials, including metal, wood, and plastic, making them versatile for various warehouse environments.

- Mobile Shelving: Mobile shelving systems are mounted on tracks, allowing them to be moved closer together to save space when not in use. This type of shelving maximizes storage density and is especially useful in warehouses with limited floor space.

Pallet Racking Systems

- Selective Pallet Racking: This is one of the most popular types of pallet racking systems, allowing for easy access to all pallets. It’s suitable for warehouses with a wide variety of products that need to be stored in bulk.

- Drive-In/Drive-Through Racking: These systems allow forklifts to drive into the rack structure, making them ideal for high-density storage of similar products. This method maximizes space but requires careful inventory management to avoid issues with stock rotation.

- Push Back Racking: Push-back systems allow pallets to be stored on a system of inclined rails. When a new pallet is added, it pushes the existing pallets back, providing first-in, last-out (FILO) inventory management.

Automated Storage and Retrieval Systems (ASRS)

- ASRS technology utilizes robotics and computer software to automate the storage and retrieval of products. This system significantly reduces labor costs and improves accuracy in order fulfillment. ASRS can be particularly beneficial for high-volume warehouses that require fast and efficient operations.

Mezzanine Flooring

- Mezzanines are elevated platforms that can be added to existing warehouse spaces. They provide additional storage space without requiring a larger footprint, making them ideal for maximizing vertical space. Mezzanines can be used for storage or as additional workspace.

Container Storage

- Containers can be an efficient way to store inventory. They can be stacked to utilize vertical space and are often used for seasonal or surplus items. Container storage provides flexibility and can be moved easily, making it a versatile solution for fluctuating inventory levels.

Benefits of Using Logistic Warehouse Storage Products

Implementing the right logistic warehouse storage products can lead to significant improvements in your inventory management practices:

- Increased Efficiency: Well-organized storage systems reduce the time spent searching for products. When items are easily accessible, order picking becomes faster and more efficient.

- Space Optimization: Effective storage solutions allow for better use of warehouse space. By maximizing vertical and horizontal space, businesses can store more inventory without expanding their facilities.

- Improved Inventory Accuracy: Logistic warehouse storage products help maintain better inventory control. With clear organization, tracking stock levels becomes more straightforward, reducing the risk of stockouts or overstock situations.

- Enhanced Safety: Proper storage systems can reduce hazards in the warehouse. For instance, secure shelving and racking systems minimize the risk of products falling and causing injuries.

Selecting the Right Logistic Warehouse Storage Products

When choosing the right logistic warehouse storage products for your operations, consider the following factors:

- Type of Products: Assess the types of products you store. Are they bulky, fragile, or perishable? Understanding the nature of your inventory will guide you in selecting appropriate storage solutions.

- Volume and Variety: Evaluate your storage needs based on inventory volume and variety. High-volume items may require different solutions compared to a warehouse with a wide range of products.

- Warehouse Layout: The layout of your warehouse can significantly impact storage efficiency. Consider how different storage solutions will fit into your existing space and how they will affect the workflow.

- Future Growth: Plan for future growth when selecting storage products. Choose solutions that can be expanded or adapted as your business evolves.

- Budget: Establish a budget for your storage solutions. While it’s essential to invest in quality products, ensure that the costs align with your operational goals and financial capabilities.

Implementing Logistic Warehouse Storage Products

Once you have selected the appropriate logistic warehouse storage products, it’s crucial to implement them effectively. Here are some steps to ensure a smooth implementation process:

- Training Staff: Ensure that your staff is trained in using new storage systems. Proper training can significantly enhance the efficiency of your warehouse operations.

- Inventory Organization: Develop a clear inventory organization system. Labeling shelves and bins can help employees quickly locate items, improving overall productivity.

- Regular Audits: Conduct regular audits of your inventory and storage systems. This practice helps maintain accuracy and identify any areas for improvement.

- Embrace Technology: Utilize technology to enhance your inventory management processes. Software solutions can provide real-time tracking of inventory levels, helping you make informed decisions about restocking and order fulfillment.

Conclusion

Effective inventory management is the backbone of successful logistics operations, and the right logistic warehouse storage products play a vital role in achieving this goal. By understanding the different types of storage solutions available, their benefits, and how to implement them effectively, businesses can enhance their warehouse operations and drive greater efficiency. Investing in quality storage products not only optimizes space and improves accessibility but also sets the stage for future growth and success in the competitive logistics landscape.

As you consider your options for logistic warehouse storage products, remember to assess your unique needs and plan for both current and future demands. With the right products in place, you can create a well-organized, efficient warehouse that meets your business goals and exceeds customer expectations.

Frequently Asked Questions:-

1) What are logistic warehouse storage products?

- Logistic warehouse storage products are various tools and systems designed to optimize the storage and organization of inventory in warehouses. These include shelving units, pallet racking systems, automated storage and retrieval systems (ASRS), mezzanine flooring, and container storage solutions. They aim to improve space utilization, accessibility, and efficiency in inventory management.

2) How do I choose the right storage products for my warehouse?

- When selecting storage products, consider factors such as the type and volume of products you store, your warehouse layout, future growth potential, and your budget. It’s important to assess the specific needs of your inventory and ensure the storage solutions you choose enhance accessibility and efficiency in your operations.

3) What are the benefits of using automated storage and retrieval systems (ASRS)?

- ASRS offers several benefits, including increased efficiency and accuracy in order fulfillment, reduced labor costs, and improved inventory management. By automating the storage and retrieval processes, businesses can enhance their operational capabilities, reduce the risk of human error, and maximize their warehouse space.

4) How can I improve safety in my warehouse using storage products?

- To improve safety, ensure that storage systems are designed to securely hold items and minimize the risk of collapse or falling products. Implementing proper shelving and racking systems, providing adequate staff training, and maintaining clear aisles and pathways can help create a safer warehouse environment. Regular audits and safety inspections are also essential.

5) How often should I conduct inventory audits?

- The frequency of inventory audits can vary based on the size of your warehouse and the volume of inventory you manage. However, it is typically suggested that audits be conducted at least quarterly. More frequent audits can help identify discrepancies, maintain inventory accuracy, and ensure that your storage systems are functioning optimally.