In the ever-evolving landscape of warehousing and logistics, automation has become the driving force behind efficiency and productivity. The Automated Storage and Retrieval System (ASRS) revolutionizes how goods are stored and retrieved, serving as a critical component of this transformation. At the heart of this innovation lies the ASRS pallet, a key element that ensures smooth operations within these automated systems. As an ASRS Pallet Manufacturer we understand the significance of crafting high-quality pallets that meet the specific needs of modern warehouses and distribution centers.

Understanding ASRS Pallets

Before diving into the intricacies of ASRS pallet manufacturing, it’s essential to grasp the concept of ASRS itself. ASRS is an automated technology designed to store and retrieve products in a warehouse or distribution center. These systems are known for their precision, speed, and efficiency, reducing human intervention and minimizing errors in inventory management.

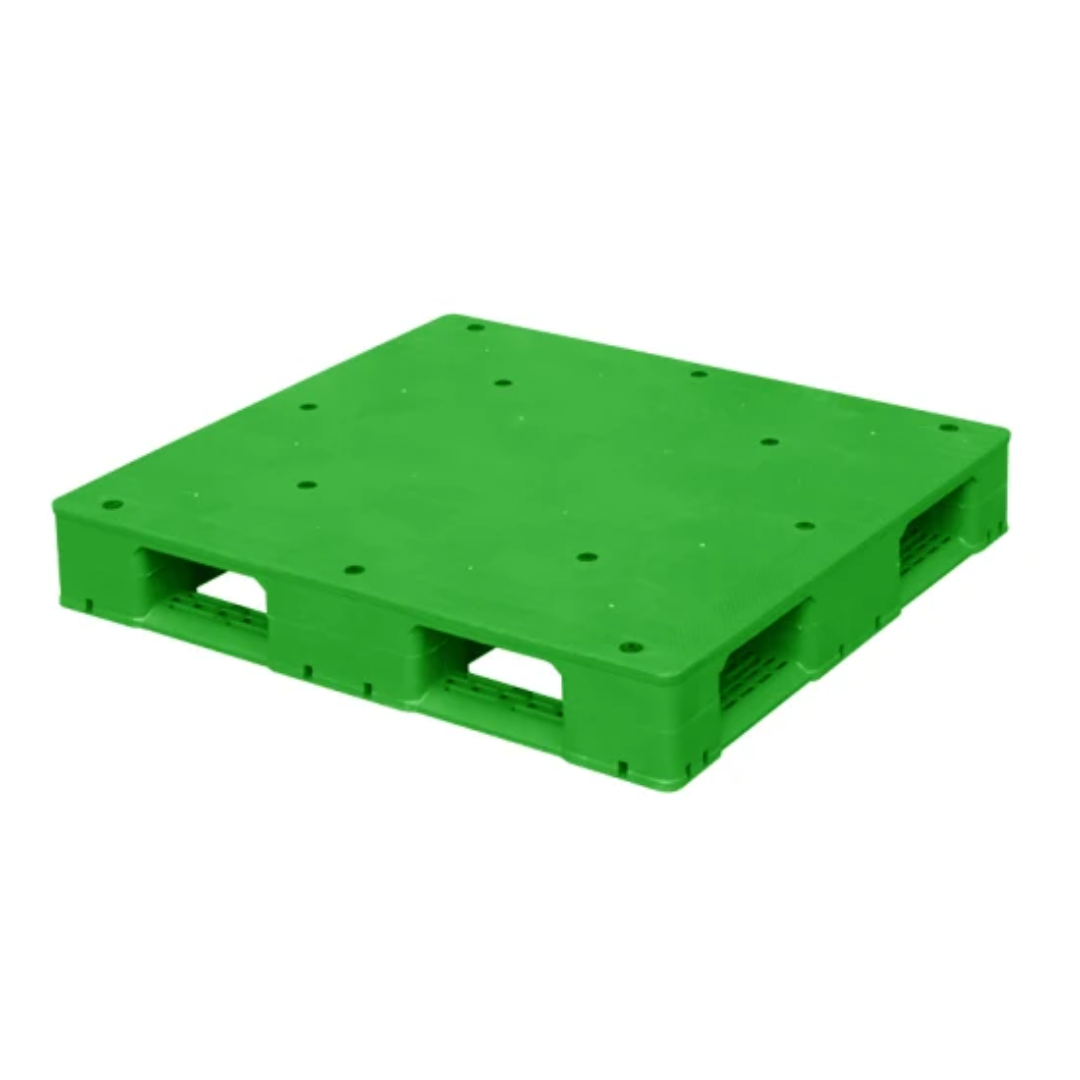

ASRS pallets, therefore, are specially designed to work seamlessly within these automated systems. They are engineered to be robust, durable, and compatible with the machinery used in ASRS environments. As an ASRS Pallet Manufacturer, we prioritize precision engineering and quality materials to ensure that our pallets can withstand the rigors of automated handling and storage.

The Importance of Choosing the Right ASRS Pallet Manufacturer

Selecting the right ASRS Pallet Manufacturer is crucial for the success of any automated storage system. The quality of the pallets has a direct impact on the overall efficiency and dependability of the ASRS. Here’s why picking the correct manufacturer is important:

- Durability and Longevity: ASRS pallets are subjected to constant movement, lifting, and stacking within automated systems. Inferior quality pallets may wear out quickly, leading to frequent replacements and increased operational costs. A reputable manufacturer ensures that their pallets are built to last, reducing downtime and maintenance expenses.

- Compatibility with ASRS Systems: ASRS systems are highly specialized, and not all pallets are suitable for use within them. A trusted ASRS pallet manufacturer understands the specific requirements of these systems and designs pallets that seamlessly integrate with the machinery, ensuring smooth operations and preventing costly disruptions.

- Customization Options: Every warehouse or distribution center has unique needs. A reliable manufacturer provides customization choices, allowing firms to design pallets to their exact needs. Whether it’s size, load capacity, or material, a good manufacturer can provide solutions that align with your operational goals.

- Compliance with Industry Standards: Quality and safety are paramount in any industrial setting. A reputable ASRS Pallet Manufacturer adheres to industry standards and regulations, ensuring that their products meet the highest quality benchmarks. This compliance not only guarantees the safety of your operations but also enhances your reputation as a responsible business.

The Manufacturing Process of ASRS Pallets

As a leading ASRS Pallet Manufacturer, we follow a meticulous manufacturing process to deliver pallets that meet the demands of modern automated systems. Our process involves several key stages:

- Design and Engineering: The process begins with the design phase, where our team of engineers collaborates with clients to understand their specific requirements. We use advanced CAD software to create detailed designs that ensure precision and compatibility with ASRS systems.

- Material Selection: The longevity and performance of ASRS pallets are highly dependent on the materials used. We carefully select high-quality materials, such as reinforced plastic, steel, or composite materials, that can withstand the rigorous demands of automated storage and retrieval.

- Prototyping: Before mass production, we create prototypes of the pallets to test their functionality and performance within ASRS environments. This step allows us to identify and address any potential issues, ensuring that the final product meets our stringent quality standards.

- Production: Once the design and prototyping stages are complete, we move on to full-scale production. Our state-of-the-art manufacturing facilities are equipped with advanced machinery that ensures precision and consistency in every pallet we produce.

- Quality Control: Quality control is a critical aspect of our manufacturing process. Each pallet undergoes rigorous testing to ensure it meets our high standards for durability, load-bearing capacity, and compatibility with ASRS systems. We also perform random inspections throughout the production process to maintain consistency.

- Customization: For clients with specific requirements, we offer customization options. Whether it’s altering the size, adding specific features, or using specialized materials, our team works closely with clients to deliver pallets that meet their unique needs.

- Final Inspection and Delivery: Before shipping the pallets to our clients, we conduct a final inspection to ensure that each pallet meets our quality benchmarks. We also provide detailed documentation and user manuals to help clients integrate the pallets seamlessly into their ASRS systems.

Innovations in ASRS Pallet Manufacturing

As a forward-thinking ASRS Pallet Manufacturer, we are committed to staying at the forefront of industry innovations. The field of automated storage and retrieval is constantly evolving, and we strive to incorporate the latest advancements into our pallet designs and manufacturing processes. Some of the innovations we are currently exploring include:

- Lightweight and High-Strength Materials: The development of new materials that are both lightweight and incredibly strong is revolutionizing the pallet industry. These materials not only reduce the weight of the pallets, making them easier to handle, but also increase their load-bearing capacity, enhancing the overall efficiency of ASRS systems.

- Smart Pallets with IoT Integration: The Internet of Things (IoT) is making its way into the world of pallets. We are exploring the integration of IoT technology into our ASRS pallets, allowing for real-time tracking, monitoring, and data collection. These smart pallets can communicate with the ASRS system, providing valuable insights into inventory management, pallet health, and system performance.

- Sustainable Manufacturing Practices: Sustainability is a key focus for us as an ASRS Pallet Manufacturer. We are continuously working to reduce our environmental footprint by adopting eco-friendly manufacturing practices, using recyclable materials, and exploring innovative ways to repurpose or recycle old pallets.

- Enhanced Ergonomics and Safety Features: Worker safety is a top priority in any industrial setting. We are incorporating ergonomic designs and safety features into our pallets to reduce the risk of injuries during manual handling. These features include anti-slip surfaces, rounded edges, and handles for easy lifting.

Why Partner with Us as Your ASRS Pallet Manufacturer?

Why Partner with Us as Your ASRS Pallet Manufacturer?

Choosing the right ASRS Pallet Manufacturer can make a significant difference in the efficiency and reliability of your automated storage system. When you collaborate with us, you can expect:

- Unmatched Expertise: With years of experience in the industry, we have honed our expertise in designing and manufacturing pallets that meet the specific demands of ASRS systems. Our team of engineers and technicians is well-versed in the latest industry trends and technologies.

- Commitment to Quality: Everything we do is based on quality principles. From the materials we use to the manufacturing processes we employ, we are committed to delivering pallets that exceed your expectations. Our stringent quality control measures ensure that each pallet meets the highest standards.

- Customization Flexibility: We understand that no two warehouses are alike. That’s why we offer extensive customization options to meet your unique requirements. Whether you need pallets in specific sizes, with specialized features, or made from certain materials, we can deliver tailored solutions.

- Innovation-Driven Approach: The world of ASRS is constantly evolving, and we are dedicated to staying ahead of the curve. Our commitment to innovation ensures that our pallets are equipped with the latest features and technologies, helping you optimize your storage and retrieval processes.

- Sustainability Focus: As a responsible ASRS Pallet Manufacturer, we are committed to reducing our environmental impact. We prioritize sustainable manufacturing practices, and our pallets are designed with longevity and recyclability in mind.

- Comprehensive Support: Our relationship with our clients doesn’t end with the delivery of pallets. We offer ongoing support and maintenance services to ensure that your pallets continue to perform optimally within your ASRS system. Our team is always accessible to answer any questions or offer support.

Conclusion

In the fast-paced world of automated storage and retrieval, the quality of your pallets plays a critical role in the efficiency and reliability of your operations. As a leading ASRS Pallet Manufacturer, we are dedicated to providing high-quality, durable, and customizable pallets that meet the unique needs of modern warehouses and distribution centers. By partnering with us, you can trust that you are investing in pallets that are designed to enhance the performance of your ASRS system, reduce operational costs, and contribute to a more sustainable future.

Frequently Asked Questions:-

1. What is an ASRS pallet?

- An ASRS pallet is a specialized pallet designed to work with Automated Storage and Retrieval Systems (ASRS). These pallets are engineered to be durable, precise, and compatible with the automated machinery used in modern warehouses and distribution centers.

2. Why are ASRS pallets important in automated systems?

- ASRS pallets are crucial because they ensure efficient and reliable storage and retrieval of goods within automated systems. Their design allows for seamless integration with ASRS machinery, minimizing errors and maximizing operational efficiency.

3. What materials are commonly used in ASRS pallet manufacturing?

- Common materials include reinforced plastic, steel, and composite materials. These materials are chosen for their strength, durability, and ability to withstand the demands of automated handling.

4. How do I choose the right ASRS pallet for my system?

- To choose the right ASRS pallet, consider factors such as load capacity, dimensions, material, and compatibility with your ASRS system. It’s also essential to consult with your ASRS provider or pallet manufacturer for recommendations based on your specific requirements.

8. Are ASRS pallets environmentally friendly?

- Many ASRS pallet manufacturers are focusing on sustainability by using recyclable materials and adopting eco-friendly manufacturing practices. Look for manufacturers that prioritize environmental considerations in their production processes.