In the ever-evolving landscape of warehousing and logistics, efficient storage solutions are paramount. Among these, stillage systems have become integral to optimizing space and managing inventory. This blog delves into the role of stillage manufacturer experts in providing tailored solutions that meet diverse needs, exploring their expertise, innovations, and how they address specific challenges in the industry.

Table of Contents

ToggleUnderstanding Stillages

What is a Stillage?

A stillage is a type of storage unit used primarily in warehouses and distribution centers. It is designed to hold goods securely and can come in various forms, including open frames, cages, or bins. These units are essential for organizing products, especially when dealing with bulk items or heavy loads. The design of stillages can significantly impact operational efficiency, making it crucial to choose the right solution.

Importance of Custom Solutions

While standard stillage units can handle many storage needs, custom solutions offer enhanced flexibility and efficiency. Custom stillages are designed to fit specific requirements, such as unique dimensions, load capacities, or special features. This customization can improve space utilization, streamline workflows, and reduce the risk of product damage.

The Role of Stillage Manufacturer Experts

Expertise in Design and Engineering

Stillage manufacturer experts bring a wealth of knowledge to the table, particularly in design and engineering. They understand the intricacies of creating stillages that are not only durable but also optimized for specific applications. Their expertise ensures that the designs meet industry standards and can withstand the rigors of daily use in demanding environments.

Innovations in Stillage Solutions

The field of stillage manufacturing is continually evolving, with advancements in materials, technology, and design. Experts in this field stay abreast of these innovations to offer state-of-the-art solutions. For instance, the use of high-strength materials and advanced welding techniques can enhance the durability and longevity of stillages, while modular designs allow for greater flexibility and adaptability.

Customization Capabilities

A key advantage of working with stillage manufacturer experts is their ability to provide customized solutions. These experts can tailor stillages to specific needs, whether it’s for unusual load sizes, specialized handling requirements, or integration with existing storage systems. Custom stillages can be designed to optimize space, improve accessibility, and enhance overall operational efficiency.

Benefits of Custom Stillages

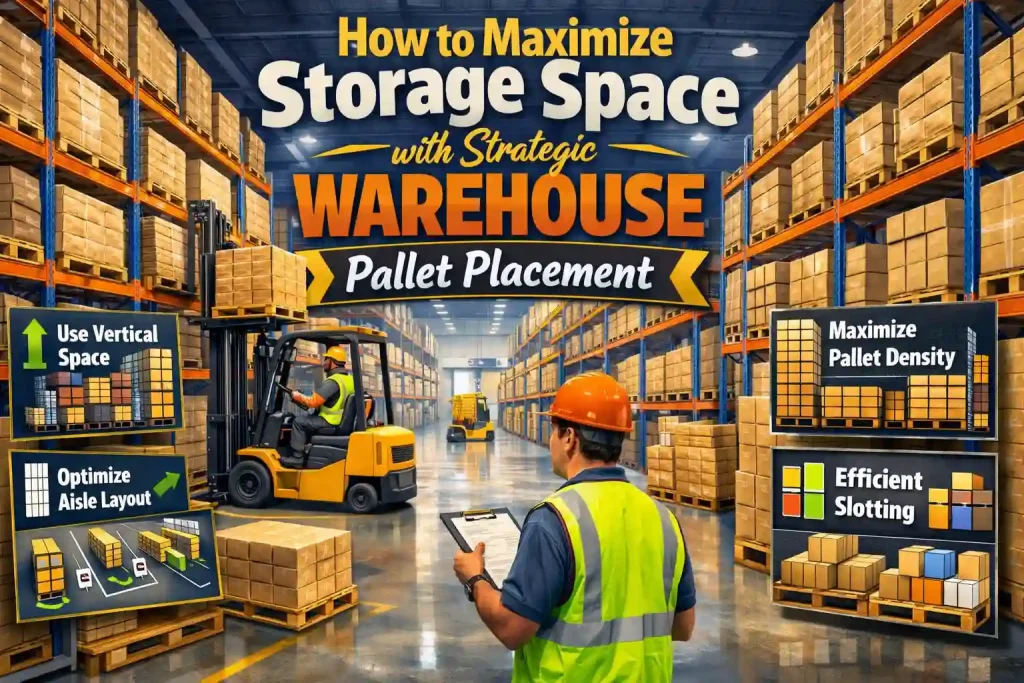

Improved Space Utilization

One of the primary benefits of custom stillages is the ability to maximize space. Standard units may not always fit perfectly within a given area, leading to wasted space and inefficiencies. Custom stillages are designed to fit precisely within the available space, allowing for better organization and increased storage capacity.

Enhanced Operational Efficiency

Custom stillages can be designed to streamline workflows and improve handling processes. For example, stillages with built-in features such as adjustable shelves, easy-to-maneuver casters, or specialized compartments can facilitate faster and more efficient product handling. This efficiency can lead to cost savings and enhanced production.

Increased Safety and Reduced Damage

Safety is a critical concern in warehousing and logistics. Custom stillages can be engineered to meet safety standards and reduce the risk of accidents. Features such as reinforced frames, secure locking mechanisms, and ergonomic design elements can help prevent injuries and minimize product damage.

Challenges in Stillage Manufacturing

Meeting Diverse Requirements

One of the challenges faced by stillage manufacturers is meeting the diverse needs of clients. Different industries and applications have unique requirements, from varying load capacities to specific dimensions. Stillage manufacturer experts must balance these needs with practical design considerations to deliver effective solutions.

Maintaining Quality and Durability

Ensuring the quality and durability of stillages is another significant challenge. Manufacturers must select appropriate materials and employ rigorous quality control measures to produce stillages that can withstand heavy use and environmental factors. This focus on quality is essential to providing long-lasting and reliable storage solutions.

Adapting to Technological Advances

The integration of new technologies into stillage systems presents both opportunities and challenges. For instance, incorporating automation or smart technology into stillages can enhance their functionality but also requires additional expertise and investment. Stillage manufacturer experts must stay informed about technological trends and evaluate their applicability to various storage solutions.

Case Studies of Custom Stillage Solutions

Retail Industry

In the retail sector, custom stillages can be designed to accommodate diverse product types and sizes. For example, a retail distribution center might require stillages with adjustable shelves to handle a range of products from small items to bulky goods. By working with stillage manufacturer experts, retailers can create solutions that improve inventory management and streamline the supply chain.

Automotive Industry

The automotive industry often requires stillages for storing and transporting heavy and bulky parts. Custom stillages designed for this industry might feature reinforced frames and specialized compartments to handle different types of automotive components. These custom solutions help ensure that parts are transported safely and efficiently, reducing the risk of damage during handling.

Food and Beverage Industry

In the food and beverage industry, stillages must meet stringent hygiene and safety standards. Custom stillages for this sector might include features such as easy-to-clean surfaces and compliance with health regulations. By collaborating with stillage manufacturer experts, food and beverage companies can ensure that their storage solutions are both functional and compliant with industry standards.

How to Choose the Right Stillage Manufacturer

Evaluate Expertise and Experience

When selecting a stillage manufacturer, it’s important to consider their expertise and experience. Look for manufacturers with a proven track record in delivering custom solutions and a deep understanding of your specific industry needs. Experienced manufacturers are more likely to provide effective solutions and anticipate potential challenges.

Assess Customization Capabilities

Make sure the manufacturer can suit your customization needs. Discuss your specific needs and evaluate their ability to design and produce stillages that meet your criteria. A manufacturer with strong customization capabilities can offer solutions tailored to your unique storage needs.

Consider Quality and Reliability

Quality and reliability are crucial factors in choosing a stillage manufacturer. Research their quality control processes and ask for references or case studies to gauge their performance. Reliable manufacturers will deliver products that meet industry standards and provide long-term value.

Conclusion

Stillage manufacturer experts play a crucial role in providing custom solutions that address the diverse needs of various industries. Their expertise in design, innovation, and customization ensures that businesses can optimize their storage solutions for efficiency, safety, and space utilization. By working with a reputable stillage manufacturer like Kole Global, companies can benefit from high-quality, tailored stillage solutions that enhance their operations and support their logistical goals.

Frequently Asked Questions:-

1. What are custom stillages, and why might I need them?

- Custom stillages are storage units designed to meet specific requirements tailored to your needs. Unlike standard stillages, which come in fixed sizes and configurations, custom stillages can be modified to fit unique dimensions, load capacities, or handling requirements. You might need custom stillages to optimize space utilization, enhance operational efficiency, or meet industry-specific regulations.

2. How do I determine if I need a custom stillage solution?

- If your storage needs involve unusual dimensions, heavy or delicate items, or integration with existing systems, a custom stillage might be beneficial. Evaluate your current storage setup and identify any inefficiencies or challenges. Consulting with a stillage manufacturer expert can help you assess whether a custom solution is necessary and how it can address your specific needs.

3. What materials are commonly used in custom stillages?

- Custom stillages can be made from various materials, depending on their intended use and required durability. Common materials include steel, aluminum, and plastic. Steel is often used for its strength and durability, while aluminum offers a lighter alternative. Plastic stillages are popular in industries requiring hygienic and lightweight solutions. The choice of material will depend on factors like load capacity, environmental conditions, and industry standards.

4. What are the typical lead times for custom stillage manufacturing?

- The lead time for custom stillage manufacturing can vary based on the complexity of the design and the manufacturer’s workload. It might take weeks or months. Factors influencing lead times include the level of customization required, material availability, and production schedules. It’s important to discuss your timeline with the manufacturer to ensure timely delivery.

5. How do I choose the right stillage manufacturer for my needs?

When selecting a stillage manufacturer, consider their expertise, experience, and ability to deliver custom solutions. Look for manufacturers with a strong track record in your industry and those who can offer tailored designs. Assess their quality control processes and request references or case studies to verify their reliability. A reputable manufacturer will provide high-quality stillages that meet your specific requirements and support your operational goals.