1. Executive Summary:

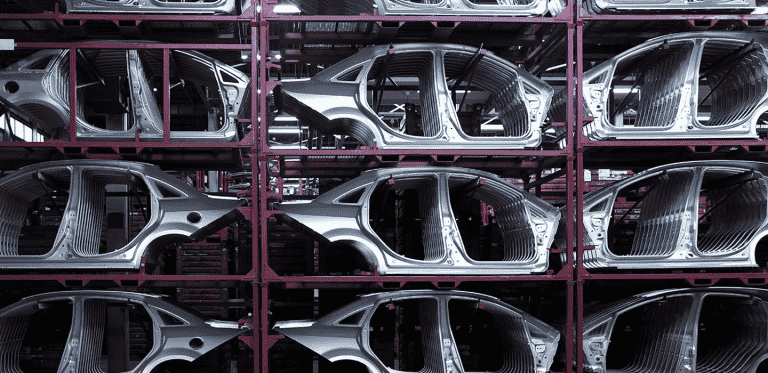

This project outlines the successful implementation of a Returnable Pallet Frame for an Automobile Company, specifically designed to store and transport car side frames from ancillary suppliers to their facility. The initiative aimed to reduce asset costs, reverse transport costs, improve quality, and minimize damages, with an added feature of GPS asset tracking.

2. Introduction:

The Automobile Company recognized the need for an efficient solution to transport car side frames from ancillary suppliers to their facility. The decision to implement a Returnable Pallet Frame was driven by the goal of optimizing the logistics process, enhancing quality, and minimizing costs associated with assets and transport.

3. Returnable Pallet Frame Features:

- Collapsible Design: The pallet frame is collapsible, allowing for efficient storage when not in use.

- Durability: Built with robust materials, the frame ensures the safe transport of car side frames while minimizing wear and tear.

- Asset Tracking via GPS: The pallet frame is equipped with GPS tracking technology,enabling real-time monitoring of the assets during transit.

- Customizable Configuration: The design allows for adjustable configurations to accommodate varying car side frame sizes.

4. Project Journey:

- Needs Assessment: A comprehensive assessment of the existing transport process identified challenges related to asset costs, transport expenses, and potential damages.

- Design and Prototyping: A custom Returnable Pallet Frame was designed, incorporating features to address the identified challenges. Prototypes were tested and refined for optimal functionality.

- GPS Integration: GPS tracking technology was integrated into the pallet frame to provide real-time visibility and traceability during transit.

- Employee Training: Staff underwent training to ensure proper handling of the pallet frames, including the utilization of GPS tracking features.

5. Benefits:

- Reduced Asset Costs: The implementation of Returnable Pallet Frames has reduced asset costs by minimizing the need for single-use packaging materials.

- Cost-Effective Reverse Transport: The collapsible design of the pallet frames has optimized reverse transport costs, reducing expenses associated with empty return trips.

- Improved Quality: The sturdy design of the frames ensures the safe transport of car side frames, contributing to improved overall product quality.

- Reduced Damages: The customized configuration of the frames and GPS tracking technology have collectively reduced damages during transit.

6. Cost and Time Savings:

- Asset Cost Reduction: The project has resulted in significant cost savings by eliminating the need for disposable packaging materials.

- Optimized Transport Costs: Collapsible frames have led to cost savings in reverse transport expenses, maximizing efficiency.

- Reduced Damages: Minimized damages have reduced the costs associated with replacements and repairs.

7. Conclusion:

The implementation of Returnable Pallet Frames with GPS tracking for car-side frame transport has proven to be a strategic and successful initiative for the Automobile Company. The project not only addressed existing challenges but also brought about substantial cost savings and quality improvements.

8. Recommendations for Future Improvements:

- Continuous GPS Monitoring Enhancement: Explore opportunities to enhance GPS tracking features for more comprehensive monitoring.

- Expand Usage: Consider expanding the usage of Returnable Pallet Frames to other components or products within the supply chain for additional benefits.

This project exemplifies the Automobile Company’s commitment to innovation, efficiency, and sustainability, showcasing how a well-designed Returnable Pallet Frame with GPS tracking can positively impact various facets of the supply chain.