1. Executive Summary:

This project details the successful implementation of Post Pallets and Stacking Frames in a Chemical Company’s warehouse for the storage of chemical bags and boxes. The strategic use of galvanized iron (GI) material ensures the safety of chemical products. The initiative focuses on space optimization, efficient handling, and overall warehouse management improvements.

2. Introduction:

The Chemical Company recognized the critical need for a robust and safe storage solution for chemical bags and boxes. The decision to implement Post Pallets and Stacking Frames, constructed with galvanized iron, was driven by the commitment to safety, space optimization, and efficient handling.

3. Post Pallets and Stacking Frames Features:

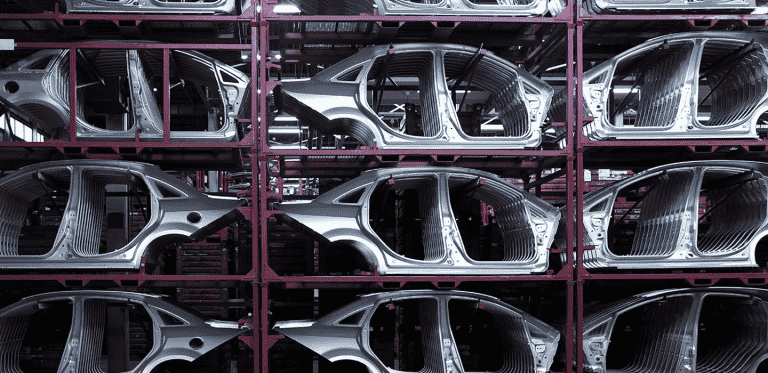

- Galvanized Iron Construction: Post Pallets are constructed with galvanized iron, ensuring chemical resistance and safety in storage.

- Customizable Configuration: The design allows for adjustable configurations to accommodate varying chemical bag and box sizes.

- Vertical Space Utilization: Stacking Frames leverage vertical space, optimizing storage capacity in the warehouse.

- Fast and Easy Handling: The design streamlines handling processes, reducing the time required for inventory management tasks.

- Collapsible Design: Post Pallets are collapsible when not in use, providing additional flexibility in

warehouse space utilization.

4. Project Journey:

- Needs Assessment: An assessment revealed challenges related to safe chemical storage, space optimization, and efficient handling.

- Design and Material Selection: Custom Post Pallets and Stacking Frames were designed, emphasizing the use of galvanized iron for chemical resistance.

- Implementation: The Post Pallets and Stacking Frames were seamlessly integrated into the warehouse operations, with staff receiving training on proper handling and safety protocols.

5. Benefits:

- Chemical Safety: The use of galvanized iron ensures chemical resistance, providing a safe storage solution for chemical products.

- Vertical Space Utilization: Stacking Frames optimize storage capacity, allowing the Chemical Company to store more products in limited warehouse space.

- Efficient Handling: The design streamlines handling processes, reducing the time required for inventory management tasks.

- Collapsible Design: Collapsible Post Pallets provide additional flexibility in warehouse space utilization when not in use.

6. Cost and Time Savings:

- Reduced Storage Costs: Stacking Frames optimize space utilization, resulting in significant cost savings associated with storage infrastructure.

- Efficient Handling: Fast and easy handling processes contribute to reduced labor costs, improving overall operational efficiency.

- Prevention of Damages: Proper storage and handling prevent damages to chemical products, reducing costs associated with replacements and spillage cleanup.

7. Conclusion:

The implementation of Post Pallets and Stacking Frames has proven to be a strategic initiative for the Chemical Company, addressing challenges related to chemical safety, space optimization, and handling efficiency. The project showcases the company’s commitment to innovative solutions and ensuring the safety of stored chemicals.

8. Recommendations for Future Improvements:

- Continuous Monitoring: Regularly monitor the performance of Post Pallets and Stacking Frames to identify areas for improvement.

- Expand Usage: Consider extending the use of these solutions to other hazardous materials or components within the supply chain for additional benefits.

This project serves as a testament to the Chemical Company’s commitment to safety, efficiency, and innovative solutions, demonstrating how well-designed storage solutions can positively impact various facets of chemical inventory management.