1. Executive Summary:

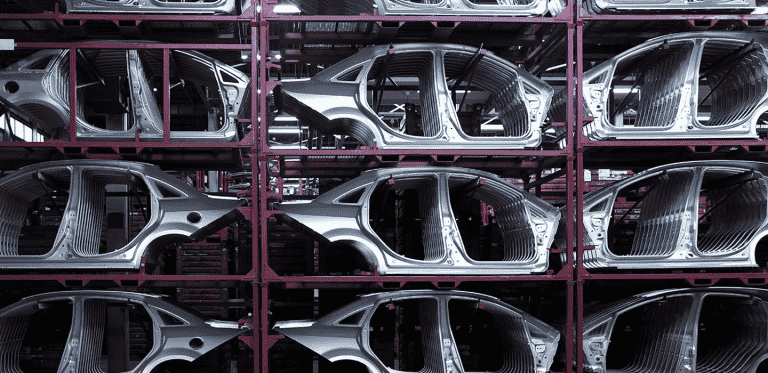

This project outlines the utilization of metal stillage for storing mattress rolls in a Mattress Company. The incorporation of stillage aims to optimize storage, enhance efficiency, and create additional floor space by going vertical.

2. Introduction:

The Mattress Company recognized the need for a more efficient and space-saving storage solution for mattress rolls. The decision to implement metal stillage was made to maximize vertical space, streamline the storage process, and reduce floor space utilization.

3. Stillage Features:

- Durable Construction: Metal stillage provides a robust and durable solution for storing heavy mattress rolls.

- Stackability: The stillage is designed for efficient vertical stacking, maximizing storage capacity. Customizable Configurations: Stillage allows for adjustable configurations to accommodate varying mattress sizes.

- Ease of Handling: Designed for easy loading, unloading, and movement using material handling equipment.

4. Implementation Journey:

- Needs Assessment: A comprehensive analysis of the existing storage system identified inefficiencies and the need for a vertical storage solution.

- Selection of Metal Stillage: After careful evaluation, metal stillage was chosen for its durability, stackability, and adaptability to varying mattress sizes.

- Installation and Integration: The stillage was seamlessly integrated into the warehouse, ensuring compatibility with existing storage infrastructure.

- Employee Training: Staff underwent training to familiarize themselves with the new stillage system, emphasizing safety protocols and efficient handling.

5. Benefits:

- Maximized Floor Space: Going vertical with metal stillage has significantly increased floor space by optimizing vertical storage.

- Efficient Retrieval: The stillage system streamlines the retrieval process, reducing manual handling time.

- Cost and Time Savings: The project has resulted in cost savings through the efficient use of space, reducing the need for additional storage facilities.

- Improved Organization: Metal stillage enhances the organization of mattress rolls, reducing the risk of damage and facilitating easy inventory management.

6. Cost and Time Savings:

- Reduced Storage Footprint: Going vertical with metal stillage has reduced the overall storage footprint, saving costs associated with expansive warehouse space.

- Efficient Retrieval: Quick and automated retrieval processes have led to time savings, improving overall operational efficiency.

7. Conclusion:

The implementation of metal stillage for mattress roll storage has proven to be a successful venture for the Mattress Company. It not only maximized floor space but also improved operational efficiency, leading to cost and time savings.

8. Recommendations for Future Improvements:

- Regular Maintenance: Implement a maintenance schedule to ensure the longevity and optimal performance of metal stillage.

- Continuous Training: Provide ongoing training to staff to keep them updated on the best practices associated with the stillage system.

This project showcases the Mattress Company’s commitment to innovation and efficiency by adopting metal stillage for mattress roll storage. It has not only addressed current storage challenges but also positioned the company for future growth and improved operational capabilities.