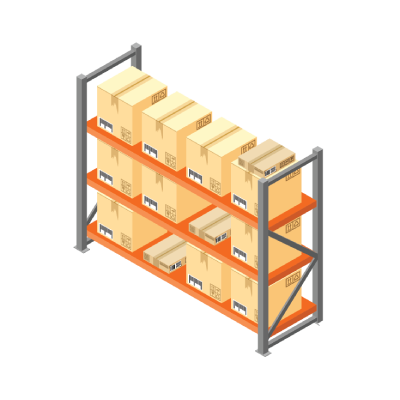

The Body Frame Pallet is a specialized storage and transportation solution for the automotive industry. Designed for durability and efficiency, it offers exceptional support for handling body frames. With its sturdy construction, this pallet ensures reliable performance even in demanding manufacturing environments.

Its configurable design adapts easily to varying body frame sizes and specifications. This flexibility makes it a versatile choice for automotive plants. Manufacturers can streamline operations without worrying about compatibility issues. Additionally, the pallet’s efficient handling capabilities simplify material movement across production lines.

By using the Body Frame Pallets, automotive plants can optimize workflow efficiency. It helps reduce downtime by ensuring smooth and organized transportation of body frames. The secure design also minimizes risks of damage, keeping materials in perfect condition.

Furthermore, the pallet enhances workplace organization. It promotes systematic storage, reducing clutter in production areas. Employees can access and move materials faster, leading to better productivity. With its robust structure, the pallet stands up to repeated use, providing long-term value.

The Body Frame Pallet is more than just a tool—it’s a reliable partner in automotive manufacturing. Its innovative features make it indispensable for plants aiming to boost efficiency and safety. Whether handling lightweight or heavy body frames, this pallet performs seamlessly.

Investing in the Body Frame Pallet is a smart choice for automotive manufacturers. It simplifies complex processes while maintaining quality and security. Transitioning to this solution helps companies stay ahead in today’s competitive industry.

This pallet isn’t just functional—it’s transformative. It bridges the gap between efficiency and reliability, ensuring your operations run smoothly. With the Body Frame Pallet, you don’t just move body frames—you move your business forward.